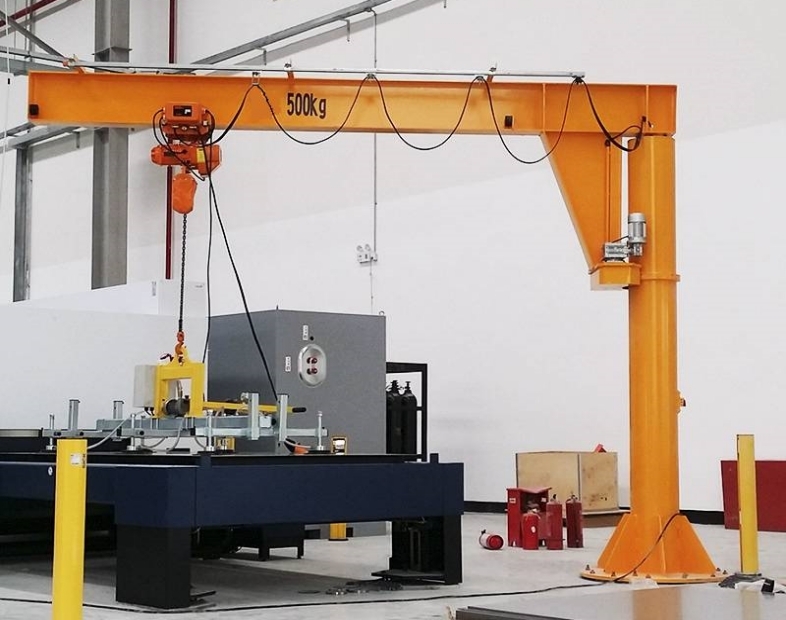

Jib Crane

| Work Load(t) | 0.5-50 |

| Span(m) | 3-25.5 |

| Lifting Height(m) | 1-12 |

| Work Class | A3-A5 |

| Power Supply | 380V,50HZ,3-Phase or Customized |

| Control Method | Pendant Control; Remote Control; Manual Control |

Overview

Jib cranes are light and convenient cranes that we have been designing to rotate at multiple angles. It can rotate 180°, 270°, 345°, 360°. Its simple structure, convenient installation, flexible rotation and enlarged working space are light crane equipment suitable for modern production.

The jib crane is composed of a column/pillar, a slewing device, a boom and an electric hoist, etc. The swing arm can be rotated according to the user's requirements. The rotating part can be operated manually or electrically.

Jib cranes are used in production lines, assembly lines, warehouses, ports, laboratories, etc. in machinery manufacturing, automobiles, shipbuilding and other modern industries.

Advantages of Jib Crane

1. Simple structure, simple and convenient operation

2. Large working space, energy saving and high efficiency.

3. Flexible 360°rotation, suitable for docks, warehouses, assembly workshops and other places.

Structure of Jib Crane

Accessories of Jib Crane:

1. Jib Arm & Support Structure

Including the jib arm, vertical mast, base plate, and mounting brackets. The structure provides strong support for lifting operations, ensuring stability while allowing 360° or limited rotation depending on the design.

2. Lifting Unit

Including electric chain hoist or wire rope hoist, load chain or wire rope, hook, and safety latch. The hoist ensures precise lifting and smooth handling for light to medium-duty materials.

3. Slewing & Trolley Mechanism

Including rotation bearings, slew drive, and trolley with running wheels. The mechanism allows the jib to rotate or the trolley to move along the arm smoothly, enabling accurate load positioning.

4. Power & Control System

Including power lines, festoon cable systems, pendant control, and optional remote control. This system ensures safe, convenient, and efficient crane operation.

5. Safety Components

Including end stops, overload protection, limit switches, and safety hooks to ensure reliable and safe operation during daily use.

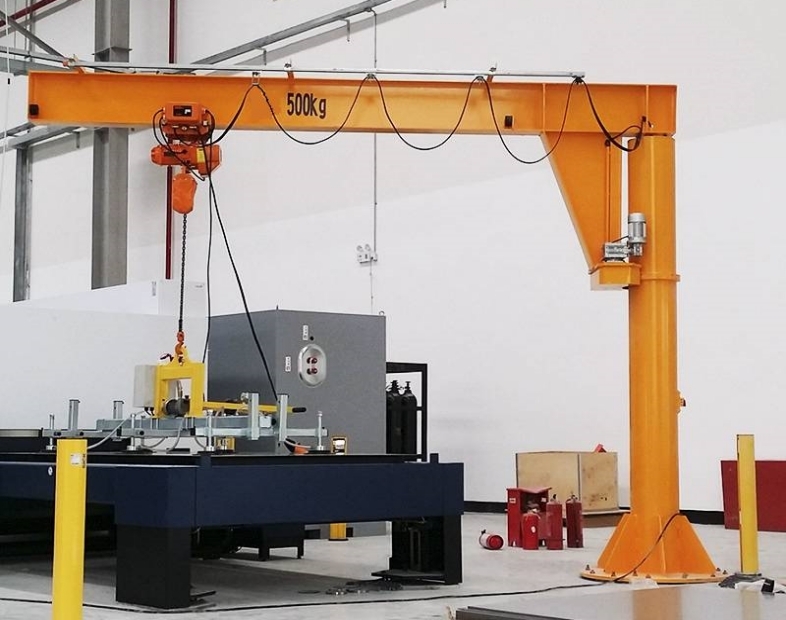

Relative Cases

In December 2024, a delegation from Indonesia visited Henan Zhonggong Group to inspect six jib cranes they had previously ordered. During their visit, the team received a detailed introduction to the jib crane products, the company’s production capabilities, and quality control procedures. They also toured the workshop to observe the manufacturing process firsthand.

The customers conducted precise measurements and confirmed that the products fully met the design and technical requirements. They expressed strong satisfaction with the product quality, manufacturing standards, and service professionalism. As a result, they planned to place a follow‑up order for 10 additional jib cranes in the first half of 2025. Tosta Crane This successful inspection strengthened the business relationship and laid a solid foundation for expanding Henan Zhonggong Group’s presence in the overseas market.

Application

The machine is suitable railway, port and machinery manufacturing and other industries rigger materials operations.Modern industry Production line, assembly line of machining, automobile industry, shipbuilding and material lifting and warehouse,wharf, Laboratory. It's an optimal lifting equipment for enterprise to improve work efficiency and working.Many occasions to replace bridge crane and gantry crane Industry, less investment, high efficiency, the product on the market after pode users praise.

Our Services:

Training:

Modular hands-on training programme

Highly qualified instructors and state-of-the-art equipment

Hands-on tasks to ensure that participants achieve all of their course goals

Training courses held at our training centre or locally

Installation:

Commissioning of crane installations

inspection and approval by our authorised crane inspectors

Spare Parts:

Fault analysis

Repairs carried out on site or at our Repair Center

Provision of genuine spare parts to replace damaged or defective parts

Recommendations for daily maintenance

Repair:

Genuine parts

Unsurpassed reliability

Long service life