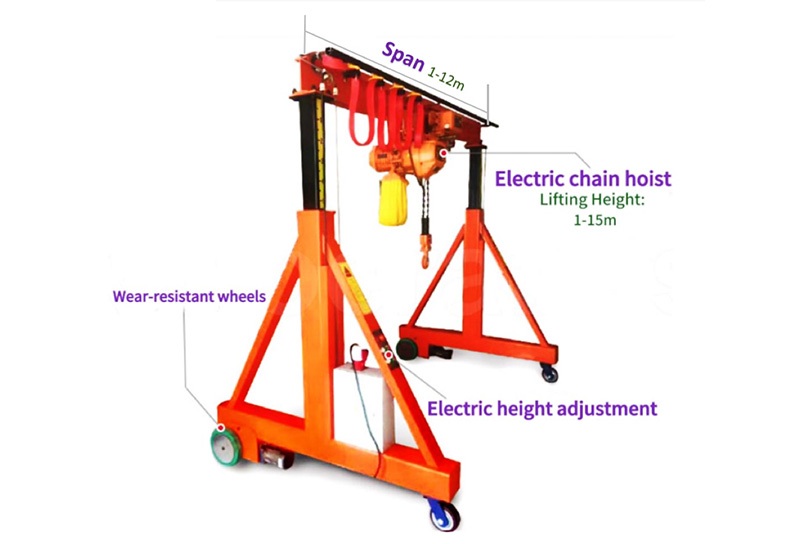

Portable Gantry Crane/Mobile Gantry Crane

| Work Load(t) | 0-20 |

| Span(m) | 1-12 |

| Lifting Height(m) | 1-15 |

| Work Class | A3-A5 |

| Power Supply | 380V,50HZ,3-Phase or Customized |

| Control Method | Pendant Control; Remote Control; |

| Main Electric Parts Brand | Schneider/ABB |

| Motor Brand | ABB/SIEMENS |

Overview

Mobile gantry cranes are designed and manufactured for small and medium-sized factories, used for loading and unloading warehouse goods, maintaining heavy equipment and transporting materials, etc.

The mobile gantry crane is a light and small equipment crane that can move and rotate 360°. Universal load wheels are installed under the outriggers, which can move freely on flat ground. The main beam of the mast and the outrigger can be quickly disassembled and installed, and it can be easily moved and disassembled from one work site to another.

Mobile gantry cranes are suitable for occasions that require lifting such as mold manufacturing companies, mines, auto repair factories, construction sites, logistics companies, mechanical processing and manufacturing companies, and warehouses.

Advantages of Portable Gantry Crane/Mobile Gantry Crane

1. Equipped with 4 universal casters wheel with brake, can rotate 360°

2. Simple structure, easy installation, good usability and efficient high performance

3. Work Load: 1-20t; Span: 1-12m

4. Suitable for auto repair factories, logistics companies,mechanical processing and manufacturing companies

Structure of Portable Gantry Crane/Mobile Gantry Crane

Detail of Portable Gantry Crane/Mobile Gantry Crane

Accessories of Portable Gantry Crane

1. Frame Structure:

Main beam and gantry legs made of high-strength steel or aluminum alloy, lightweight and easy to assemble, providing stable overall support.

2. Lifting System:

Electric or manual hoist, wire rope or chain, pulleys, and safety hook for smooth and reliable lifting operations.

3. Mobility System:

Heavy-duty caster wheels with locking devices, allowing easy movement and stable positioning without rail installation.

4. Adjustable System:

Telescopic legs with locking pins and bolts, enabling flexible adjustment of lifting height and span.

5. Control System:

Pendant control or remote control (optional) with power cables for simple and safe operation.

6. Safety Devices:

Overload protection, wheel brakes, and safety hooks with anti-unhooking design to ensure secure lifting.

Related Cases:

The 5 sets of portable gantry cranes manufactured by Henan Zhonggong Group were successfully exported to a customer in Canada. After arrival, the cranes were smoothly assembled and put into operation at the customer’s site.

Designed for flexible material handling, these portable gantry cranes feature easy installation, convenient movement, and stable lifting performance. According to customer feedback, the cranes greatly improved on-site lifting efficiency and adaptability across different work areas. The customer highly praised the product quality and expressed strong satisfaction with the overall performance and reliability.

Application

Mobile gantry cranes are suitable for occasions that require lifting such as mold manufacturing companies, mines, auto repair factories, construction sites, logistics companies, mechanical processing and manufacturing companies, and warehouses.

Our Services:

Training:

Modular hands-on training programme

Highly qualified instructors and state-of-the-art equipment

Hands-on tasks to ensure that participants achieve all of their course goals

Training courses held at our training centre or locally

Installation:

Commissioning of crane installations

inspection and approval by our authorised crane inspectors

Spare Parts:

Fault analysis

Repairs carried out on site or at our Repair Center

Provision of genuine spare parts to replace damaged or defective parts

Recommendations for daily maintenance

Repair:

Genuine parts

Unsurpassed reliability

Long service life