Double Girder Overhead Crane

| Work Load(t) | 5-550 |

| Span(m) | 7.5-35.5 |

| Lifting Height(m) | 5-30m |

| Work Class | A3-A7 |

| Power Supply | 380V,50HZ,3-Phase or Customized |

| Control Method | Pendant Control; Remote Control;Cabinet Control |

| Main Electric Parts Brand | Schneider/ABB |

| Motor Brand | ABB/SIEMENS |

| Protection Level | Ip55 |

| Working Temperature | -20℃-40℃ |

Overview

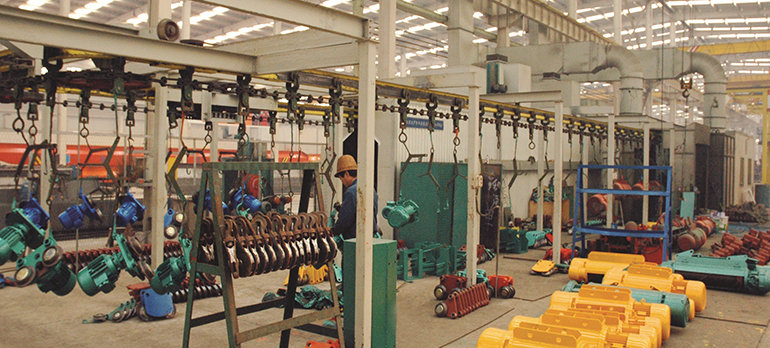

Henan Zhonggong Group, as a well renowned crane producer in China, we offer global customers an excellent double girder overhead cranes. Double girder overhead cranes are usually used in open warehouses, railways and other places to carry out common loading, unloading and material handling tasks. It is a heavy-duty bridge crane that is frequently used.

Advantages of double girder overhead crane

1. Used for lifting heavy materials in plants, warehouse, and material stocks

2. Lifting capacity: 5-550T; Span: 7.5-35.5m

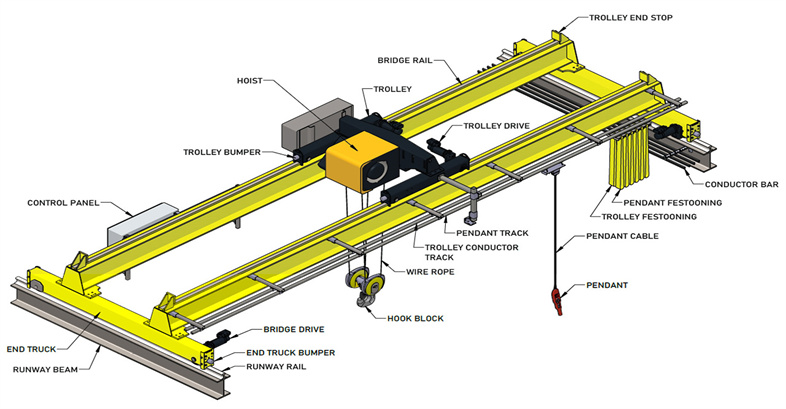

3. Composed with girder frame, crane travel device, and the trolley with lifting and moving device

4. Can be customized according to customer needs

Structure of Double Girder Overhead Crane:

Accessories of Double Girder Overhead Crane:

1.Metal structure components

Including main girders and end girders. The main girder mostly adopts I-steel or a composite section of steel sections and steel plates. The end girder is used to connect the two ends of the main girder and support the entire crane structure.

2.Hoisting mechanism components

Including electric hoists, steel wire ropes, pulleys, hooks, etc. The electric hoist is the core of the hoisting mechanism. The steel wire rope connects the hook, pulley block and drum, the pulley is used to guide the steel wire rope, and the hook is used to bear and lift the load.

3.Traveling mechanism components

Mainly including wheel sets, motors, reducers, couplings, brakes, etc. The wheel sets are installed at the bottom of the end girders and run along the rails; the motor provides power, which is transmitted to the wheels through components such as reducers and couplings, and the brake is used to control the crane's stop.

4.Electrical control components

Including wires and cables, remote controls, travel switches, control boxes, etc. Wires and cables are used to transmit electrical energy, remote controls and control boxes are used to operate the crane, and travel switches are used to limit the movement position or stroke of the crane.

5.Safety protection components

Including overload limiters, bumpers, anti-unhooking devices, etc. The overload limiter can prevent the crane from operating overloaded, the bumper is used to reduce the impact force when the crane collides, and the anti-unhooking device can prevent the load on the hook from accidentally falling off.

Different Types Of European Bridge Crane For Sale

Different Types Of European Bridge Crane For Sale:

Europe Standard Double Girder Overhead Crane:

Europe Standard Double Girder Overhead Crane is composed of box type bridge frame, lifting trolley, crane traveling mechanism, and electrical system. It is an excellent choice where high speeds and heavy service are required. As the widely used hoisting machinery currently especially is suitable for working at warehouses and freight yard and other department it is prohibited to use the equipment in the combustible, explosive or corrosives environment.

Related Cases:

Euro Double Girder Crane for Inner Mongolia Energy Group Project :

The 17, QD32/10t european double girder overhead cranes produced by Henan Zhonggong Group for Jinshan Third thermal Power Plant of Inner Mongolia Energy Group were successfully launched. Now they have been installed in the customer’s factory and successfully put into use. Customer feedback, our European double beam crane has brought great convenience to their production, excellent quality, very satisfied.

Application

Double girder overhead cranes are usually used in open warehouses, railways and other places to carry out common loading, unloading and material handling tasks. It is a heavy-duty bridge crane that is frequently used.

Our Services:

Training

Modular hands-on training programme

Highly qualified instructors and state-of-the-art equipment

Hands-on tasks to ensure that participants achieve all of their course goals

Training courses held at our training centre or locally

Installation

Commissioning of crane installations

inspection and approval by our authorised crane inspectors

Spare Parts:

Fault analysis

Repairs carried out on site or at our Repair Center

Provision of genuine spare parts to replace damaged or defective parts

Recommendations for daily maintenance

Repair:

Genuine parts

Unsurpassed reliability

Long service life