Electromagnetic Overhead Crane

| Work Load(t) | 5-500 |

| Span(m) | 7.5-45 |

| Lifting Height(m) | 5-30 |

| Work Class | A5-A8 |

| Power Supply | 380V,50HZ,3-Phase or Customized |

| Control Method | Pendant Control; Remote Control;Cabinet Control |

| Main Electric Parts Brand | Schneider/ABB |

| Motor Brand | ABB/SIEMENS |

| Protection Level | Ip65 |

| Working Temperature | -20℃-40℃ |

Overview

Electromagnetic Overhead crane is developed from the bridge double-girder crane. The fuselage has a detachable electromagnetic chuck and a configured operating system to control the transportation and lifting of metal objects by the electromagnetic chuck. It is suitable for indoor or outdoor fixing, crossing, loading and unloading or transporting metal products and materials with permeability, such as steel ingots, structural steel, iron, scrap iron, scrap steel and other materials.

Types of Electromagnetic Lifting Magnets:

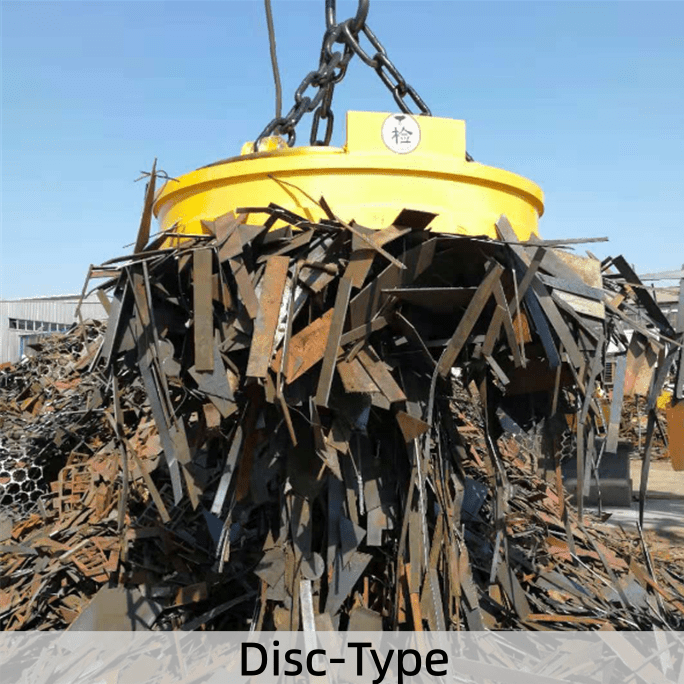

1.Disc-Type

Including main girders and end girders. The main girder mostly adopts I-steel or a composite section of steel sections and steel plates. The end girder is used to connect the two ends of the main girder and support the entire crane structure.

2.Rectangular-Type

Designed with a flat, broad surface for efficient handling of plate-shaped materials like steel sheets and metal plates.

3.Bar-Type

With a long, narrow magnetic face and concentrated force, it is suitable for precise handling and sorting of elongated items such as pipes and bars.

4.Custom-Shaped Type

Custom-shaped to match specific workpiece contours. It optimizes magnetic force distribution for handling non-standard or irregular metal parts.

Advantages of electromagnetic overhead crane

1. A specialized product for lifting and moving steel products, steel plates and steel pipes

2. Electromagnet spreader is the unique part comparing with general double girder bridge crane

3. Work load: 5~/500t; Span: 7.5-45m

4. High work efficiency, frequency conversion speed regulation

Related Cases:

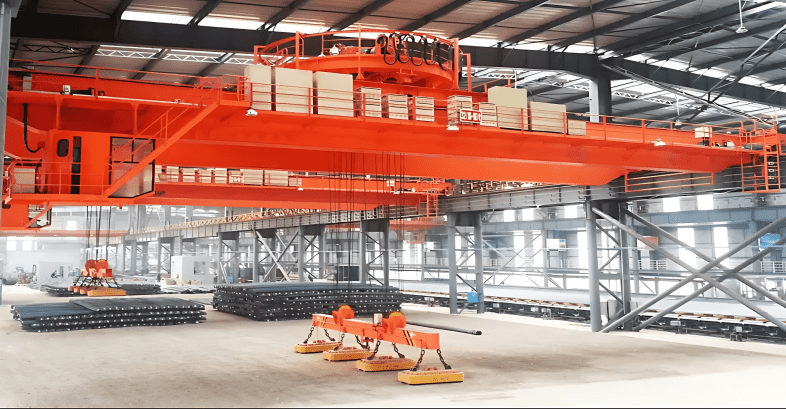

The electromagnetic overhead crane supplied by Zhonggong Group has been successfully installed and officially put into operation at a steel enterprise. The electromagnetic overhead crane is mainly used for handling steel plates and other magnetic materials. Featuring a double girder overhead crane structure combined with a high-performance electromagnetic lifting beam, the crane enables the lifting of multiple steel plates at one time, significantly improving material handling efficiency and reducing manual operations. During operation, the crane runs smoothly with strong magnetic force and stable load control. Equipped with essential safety protection devices, it fully meets the requirements of high-frequency and heavy-duty operations in steel production.

Application

Mainly used for processing magnetic metal products and materials, such as garbage disposal sites, material processing, etc.

Our Services:

Training:

Modular hands-on training programme

Highly qualified instructors and state-of-the-art equipment

Hands-on tasks to ensure that participants achieve all of their course goals

Training courses held at our training centre or locally

Installation:

Commissioning of crane installations

inspection and approval by our authorised crane inspectors

Spare Parts:

Fault analysis

Repairs carried out on site or at our Repair Center

Provision of genuine spare parts to replace damaged or defective parts

Recommendations for daily maintenance

Repair:

Genuine parts

Unsurpassed reliability

Long service life