Coil Handling Cranes

| Customized Work Load | Low and medium-duty standard crane |

Typical performance in the application |

|

| Duty cydles (EN13001-1) | Up to 8 million | 250000-500000 | 1-2 million |

| Load spectrum(EN13001-1) | Up to Q5 | Q3-Q4 | Q4-Q5 |

| FLM 1.0011998 | Up to M8 | M5-M6 | M7-M8 |

| Main trolley | Tailored open winch with or without slewing |

Standard hoist | Non-slewing tailored open winc |

| Lfting device | Magnet beam/Magnet beam with slewing /Single magnet/Vacuum lifter/Tong/C-hook |

Magnet beam/Magnet beam with slewing /Single magnet//Vacuum ifter/Tong/C-hook |

Non-Slewing magnet beam |

| Work Load | Customized | 0.4-80 tons | 5-60 tons |

| Span | Customized | Tailored | 15-40 m |

| Lifting height,max. | Customized | 3-200 m | 3-18 m |

| Bridge/Trolley travel speed | Customized | 20-40/20-32 m/min | 50-150/30-60 m/min |

| Programmable Logic Controller (PLC) |

Standard | Option | Standard |

| Manual/Automated control | Cabin/Radio | Cabin/Radio/Pendant | Cabin |

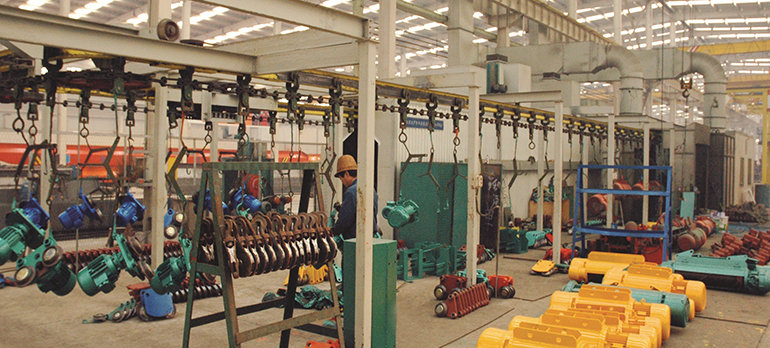

Overview

A coil handling crane handles metal bars, plates, and coils during machining processes. They can be designed for both indoor and outdoor use. Due to the wide variety of materials they need to handle, such a crane can be fitted with a variety of lifting devices that change with the nature of the material.

Our crane is designed for traveling a long distance quickly to keep duty cycles short using specialized hook extensions for plates, tubes, rolls or coils up to 80 tons. It can be equipped with Smart Features such as Load Positioning, Sway Control, and Overload Protection to shorten handling times, reduce wear on the crane, extend its life and speed up workflow. Tailoring provides you with attachments for any steel products, and additional capacity, as per your requirements.

Advantages of Coil Handling Cranes:

1.Traveling speeds up to 150 m/min

2.Up to 8 million duty cycles

3.Wide range of lifting attachments for different types of materials handling

4.WMS or CMS for material flow

5.Single or multi-trolley

6.Manual,semi-and fully automated functions

7.Programmable logic controller(PLC) to control &monitor the crane

8.Crane can be controlled with a radio remote controller or in a cabin

9.Smart Features

Accessories of Coil Handling Crane:

1. Main Steel Structure

Including double girders and end carriages, designed for high load capacity and stable operation when handling steel coils.

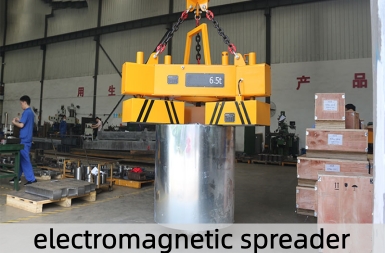

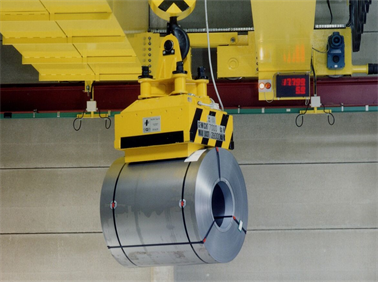

2. Coil Lifting Device

Including C-hook, coil grab, or electromagnetic spreader, specially designed to safely lift and position steel coils in horizontal or vertical orientation.

3. Hoisting Mechanism

Including heavy-duty hoist, wire rope, drum, pulleys, and hook block, providing smooth and precise lifting control.

4. Traveling Mechanism

Including wheel sets, motors, gear reducers, couplings, and brakes, ensuring stable crane traveling along runway rails.

5. Electrical & Control System

Including control cabinet, power supply system, pendant control or remote control for efficient crane operation.

6. Safety Devices

Including overload limiter, limit switches, anti-sway devices, and emergency stop system to ensure safe coil handling operations.

Application:

A coil handling crane handles metal bars, plates, and coils during machining processes. They can be designed for both indoor and outdoor use. Due to the wide variety of materials they need to handle, such a crane can be fitted with a variety of lifting devices that change with the nature of the material.

Our Services:

Training:

Modular hands-on training programme

Highly qualified instructors and state-of-the-art equipment

Hands-on tasks to ensure that participants achieve all of their course goals

Training courses held at our training centre or locally

Installation:

Commissioning of crane installations

inspection and approval by our authorised crane inspectors

Spare Parts:

Fault analysis

Repairs carried out on site or at our Repair Center

Provision of genuine spare parts to replace damaged or defective parts

Recommendations for daily maintenance

Repair:

Genuine parts

Unsurpassed reliability

Long service life